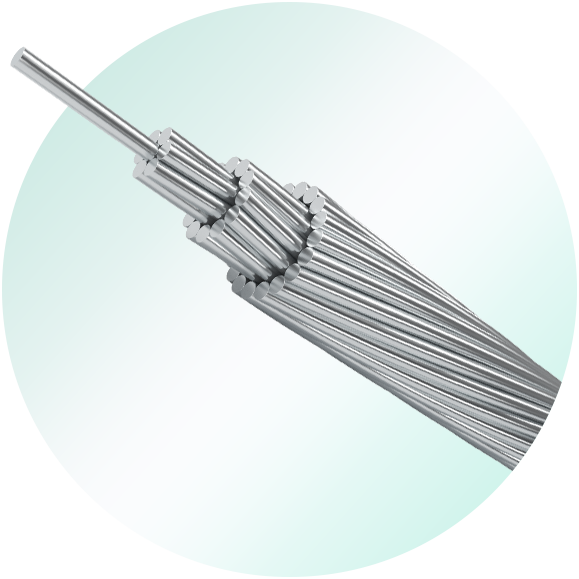

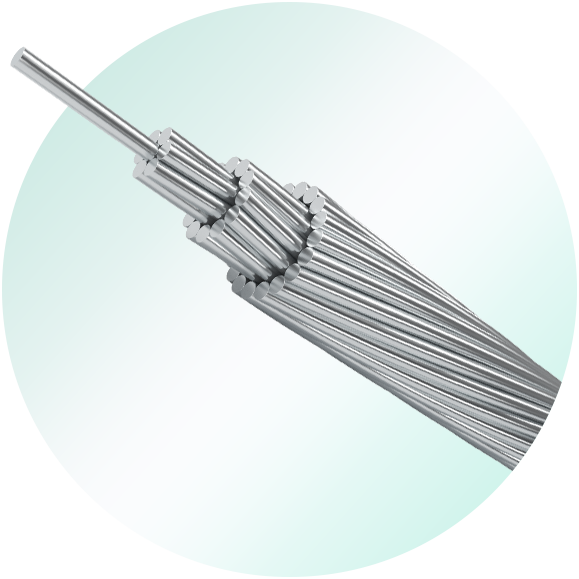

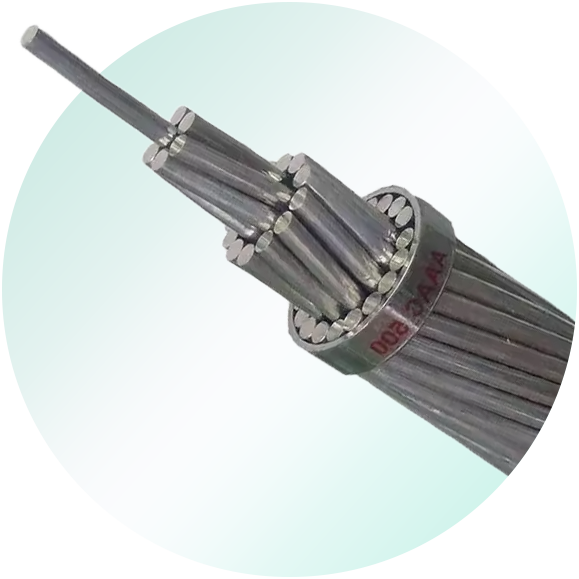

AAAC-All Aluminum Alloy Conductor

All Aluminum Alloy Conductor (AAAC) is a concentric-lay-stranded conductor made out of high strength aluminum magnesium-silicon alloy.

Home > Products > Bare Conductor

All Aluminum Alloy Conductor (AAAC) is a concentric-lay-stranded conductor made out of high strength aluminum magnesium-silicon alloy.

AAAC is used as a bare overhead conductor for primary and secondary power distribution and transmission lines, on aerial circuits that require a larger mechanical resistance than AAC, and a better corrosion resistance than ACSR.

All Aluminum Alloy Conductor (AAAC) is a concentric-lay-stranded conductor made out of high strength aluminum magnesium-silicon alloy. AAAC should have alternating lay between each layer and the outer layer shall be a right hand direction(Optional).

The sag characteristics and the strength-to-weight ratio of AAAC is better than both AAC / ACSR. The conductor has a higher resistance to corrosion than ACSR. It also has the good characteristics as simple structure, convenient installation and maintenance, low cost large transmission capacity.

Concentric-Lay-Stranded Aluminum-Alloy 6201-T81 Conductors

Conductors for Overhead Lines-Round Wire Concentric Lay stranded Conductors

Conductors - Bare Overhead - Aluminum and Aluminum Alloy

Round wire concentric lay overhead electrical stranded conductors

Round wire concentric lay overhead electrical stranded conductors

| Code Name | Area | Stranding and Wire Diameter | Approx. Overall Diameter | Unit Weight | Rated Strength |

Max. DC Resistance at 20℃ | |

| AWG or MCM | mm2 | No./mm | mm | kg/km | kN | Ohm/km | |

| AKRON | 30.58 | 15.5 | 7/1.68 | 5.04 | 43 | 4.92 | 2.159 |

| ALTON | 48.69 | 24.7 | 7/2.12 | 6.36 | 68 | 7.83 | 1.356 |

| AMES | 77.47 | 39.2 | 7/2.67 | 8.01 | 108 | 12.4 | 0.8547 |

| AZUSA | 123.3 | 62.4 | 7/3.37 | 10.11 | 171 | 18.9 | 0.5365 |

| ANAHEIM | 155.4 | 78.6 | 7/3.78 | 11.34 | 216 | 23.8 | 0.4264 |

| AMHERST | 195.7 | 99.3 | 7/4.25 | 12.75 | 273 | 30.0 | 0.3373 |

| ALLIANCE | 246.9 | 125 | 7/4.77 | 14.31 | 343 | 37.8 | 0.2678 |

| BUTTE | 312.8 | 159 | 19/3.26 | 16.30 | 435 | 46.5 | 0.2112 |

| CANTON | 394.5 | 200 | 19/3.66 | 18.30 | 549 | 58.6 | 0.1676 |

| CAIRO | 465.4 | 236 | 19/3.98 | 19.90 | 649 | 69.2 | 0.1417 |

| DARIEN | 559.5 | 284 | 19/4.36 | 21.80 | 778 | 83.1 | 0.1181 |

| ELGIN | 652.4 | 331 | 19/4.71 | 23.55 | 908 | 97.0 | 0.1012 |

| FLINT | 740.8 | 375 | 37/3.59 | 25.13 | 1028 | 107 | 0.08944 |

| GREELEY | 927.2 | 470 | 37/4.02 | 28.14 | 1289 | 135 | 0.07133 |

| — | 1077.4 | 547 | 61/3.38 | 30.42 | 1502 | 156 | 0.06120 |

| — | 1165.1 | 590 | 61/3.51 | 31.59 | 1620 | 167 | 0.05675 |

| — | 1259.6 | 638 | 61/3.65 | 32.85 | 1751 | 181 | 0.05248 |

| — | 1348.8 | 685 | 61/3.78 | 34.02 | 1878 | 194 | 0.04893 |

| — | 1439.2 | 729 | 61/3.90 | 35.10 | 1999 | 207 | 0.04597 |

| Code | Old Code |

Area | Number of Wires | Diameter | Mass per Unit length |

Rated Strength |

Max. DC Resistance at 20℃ | |

| Wire | Cond. | |||||||

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | ||

| 19-AL3 | BOX | 18.8 | 7 | 1.85 | 5.55 | 51.4 | 5.55 | 1.7480 |

| 24-AL3 | ACACIA | 23.8 | 7 | 2.08 | 6.24 | 64.9 | 7.02 | 1.3828 |

| 30-AL3 | ALMOND | 30.1 | 7 | 2.34 | 7.02 | 82.2 | 8.88 | 1.0926 |

| 35-AL3 | CEDAR | 35.5 | 7 | 2.54 | 7.62 | 96.8 | 10.46 | 0.9273 |

| 42-AL3 | DEODAR | 42.2 | 7 | 2.77 | 8.31 | 115.2 | 12.44 | 0.7797 |

| 48-AL3 | FIR | 47.8 | 7 | 2.95 | 8.85 | 130.6 | 14.11 | 0.6875 |

| 60-AL3 | HAZEL | 59.9 | 7 | 3.30 | 9.90 | 163.4 | 17.66 | 0.5494 |

| 72-AL3 | PINE | 71.6 | 7 | 3.61 | 10.80 | 195.6 | 21.14 | 0.4591 |

| 84-AL3 | HOLLY | 84.1 | 7 | 3.91 | 11.70 | 229.5 | 24.79 | 0.3913 |

| 90-AL3 | WILLOW | 89.7 | 7 | 4.04 | 12.10 | 245.0 | 26.47 | 0.3665 |

| 119-AL3 | OAK | 118.9 | 7 | 4.65 | 14.00 | 324.5 | 35.07 | 0.2767 |

| 151-AL3 | MULBERRY | 150.9 | 19 | 3.18 | 15.90 | 414.3 | 44.52 | 0.2192 |

| 181-AL3 | ASH | 180.7 | 19 | 3.48 | 17.40 | 496.1 | 53.31 | 0.1830 |

| 211-AL3 | ELM | 211.0 | 19 | 3.76 | 18.80 | 579.2 | 62.24 | 0.1568 |

| 239-AL3 | POPLAR | 239.4 | 37 | 2.87 | 20.10 | 659.4 | 70.61 | 0.1387 |

| 303-AL3 | SYCAMORE | 303.2 | 37 | 3.23 | 22.60 | 835.2 | 89.40 | 0.1095 |

| 362-AL3 | UPAS | 362.1 | 37 | 3.53 | 24.70 | 997.5 | 106.82 | 0.0917 |

| 479-AL3 | YEW | 479.0 | 37 | 4.06 | 28.40 | 1319.6 | 141.31 | 0.0693 |

| 498-AL3 | TOTARA | 498.1 | 37 | 4.14 | 29.00 | 1372.1 | 146.93 | 0.0666 |

| 587-AL3 | RUBUS | 586.9 | 61 | 3.50 | 31.50 | 1622.0 | 173.13 | 0.0567 |

| 659-AL3 | SORBUS | 659.4 | 61 | 3.71 | 33.40 | 1822.5 | 194.53 | 0.0505 |

| 821-AL3 | ARAUCARIA | 821.1 | 61 | 4.14 | 37.30 | 2269.4 | 242.24 | 0.0406 |

| 996-AL3 | REDWOOD | 996.2 | 61 | 4.56 | 41.00 | 2753.2 | 293.88 | 0.0334 |

| Code Number |

Area | Number of Wires | Diameter | Mass per Unit Length | Rated Strength | Max. DC Resistance at 20℃ | |

| Wire | Cond. | ||||||

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | |

| 16 | 15.9 | 7 | 1.70 | 5.1 | 43 | 4.44 | 2.0742 |

| 25 | 24.2 | 7 | 2.10 | 6.3 | 66 | 6.77 | 1.3593 |

| 35 | 34.4 | 7 | 2.50 | 7.5 | 94 | 9.60 | 0.9591 |

| 50 | 49.5 | 7 | 3.00 | 9.0 | 135 | 13.82 | 0.6660 |

| 50 | 48.3 | 19 | 1.80 | 9.0 | 133 | 13.50 | 0.6849 |

| 70 | 65.8 | 19 | 2.10 | 10.5 | 181 | 18.38 | 0.5032 |

| 95 | 93.3 | 19 | 2.50 | 12.5 | 256 | 26.05 | 0.3551 |

| 120 | 117 | 19 | 2.80 | 14.0 | 322 | 32.68 | 0.2831 |

| 150 | 147.1 | 37 | 2.25 | 15.8 | 405 | 41.09 | 0.2256 |

| 185 | 181.6 | 37 | 2.50 | 17.5 | 500 | 50.73 | 0.1828 |

| 240 | 242.5 | 61 | 2.25 | 20.3 | 670 | 67.74 | 0.1371 |

| 300 | 299.4 | 61 | 2.50 | 22.5 | 827 | 83.63 | 0.1110 |

| 400 | 400.1 | 61 | 2.89 | 26.0 | 1104 | 111.70 | 0.0831 |

| 500 | 499.8 | 61 | 3.23 | 29.1 | 1379 | 139.60 | 0.0665 |

| 625 | 626.2 | 91 | 2.96 | 32.6 | 1732 | 174.90 | 0.0531 |

| 800 | 802.1 | 91 | 3.35 | 36.9 | 2218 | 224.00 | 0.0415 |

| 1000 | 999.7 | 91 | 3.74 | 41.1 | 2767 | 279.20 | 0.0333 |

| Code Name | Stranding and Wire Diameter |

Approx. Overall Diameter |

Cross- sectional Area |

Approx. Weight | Break Load |

Equiv. Aluminium Area |

Max. DC Resistance at 20℃ |

| No./mm | mm | mm2 | kg/km | KN | mm2 | Ω/km | |

| Diamond | 7/2.50 | 7.50 | 34.36 | 94 | 9.64 | 29.3 | 0.9670 |

| Dolomite | 7/2.75 | 8.25 | 41.58 | 113 | 11.6 | 35.4 | 0.7990 |

| Emerald | 7/3.00 | 9.00 | 49.48 | 135 | 13.9 | 42.2 | 0.6710 |

| Garnet | 7/3.75 | 11.30 | 77.28 | 211 | 21.7 | 65.8 | 0.4300 |

| Jade | 7/4.50 | 13.50 | 111.3 | 304 | 31.2 | 94.8 | 0.2980 |

| Jasper | 7/4.75 | 14.30 | 124.0 | 339 | 34.8 | 106 | 0.2680 |

| Opal | 19/3.25 | 16.30 | 157.6 | 433 | 44.2 | 134 | 0.2120 |

| Patronite | 19/3.50 | 17.50 | 182.8 | 503 | 51.3 | 155 | 0.1830 |

| Pearl | 19/3.75 | 18.80 | 209.8 | 576 | 58.8 | 178 | 0.1590 |

| Ruby | 37/3.00 | 21.00 | 261.6 | 721 | 73.5 | 221 | 0.1280 |

| Ruthenium | 37/3.25 | 22.80 | 307.0 | 845 | 86.1 | 260 | 0.1090 |

| Rutile | 19/4.75 | 23.80 | 336.7 | 924 | 94.4 | 285 | 0.0991 |

| Sapphire | 37/3.75 | 26.30 | 408.5 | 1120 | 115.0 | 345 | 0.0819 |

| Spinel | 61/3.25 | 29.30 | 506.1 | 1400 | 135.0 | 427 | 0.0662 |

| Tantalum | 61/3.50 | 31.50 | 586.9 | 1620 | 156.0 | 495 | 0.0572 |

| Topaz | 61/3.75 | 33.80 | 673.4 | 1860 | 179.0 | 568 | 0.0498 |

| Code Number |

Area | Number of Wires | Diameter | Linear Mass |

Rated Strength |

Max. DC Resistance at 20℃ | |

| Wire | Cond. | ||||||

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | |

| 16 | 18.4 | 7 | 1.83 | 5.49 | 50.4 | 5.43 | 1.7896 |

| 25 | 28.8 | 7 | 2.29 | 6.86 | 78.7 | 8.49 | 1.1453 |

| 40 | 46 | 7 | 2.89 | 8.68 | 125.9 | 13.58 | 0.7158 |

| 63 | 72.5 | 7 | 3.63 | 10.90 | 198.3 | 21.39 | 0.4545 |

| 100 | 115 | 19 | 2.78 | 13.90 | 316.3 | 33.95 | 0.2877 |

| 125 | 144 | 19 | 3.10 | 15.50 | 395.4 | 42.44 | 0.2302 |

| 160 | 184 | 19 | 3.51 | 17.60 | 506.1 | 54.32 | 0.1798 |

| 200 | 230 | 19 | 3.93 | 19.60 | 632.7 | 67.91 | 0.1439 |

| 250 | 288 | 19 | 4.39 | 22.00 | 790.8 | 84.88 | 0.1151 |

| 315 | 363 | 37 | 3.53 | 24.70 | 998.9 | 106.95 | 0.0916 |

| 400 | 460 | 37 | 3.98 | 27.90 | 1268.4 | 135.81 | 0.0721 |

| 450 | 518 | 37 | 4.22 | 29.60 | 1426.9 | 152.79 | 0.0641 |

| 500 | 575 | 37 | 4.45 | 31.20 | 1585.5 | 169.76 | 0.0577 |

| 560 | 645 | 61 | 3.67 | 33.00 | 1778.4 | 190.14 | 0.0516 |

| 630 | 725 | 61 | 3.89 | 35.00 | 2000.7 | 213.90 | 0.0458 |

| 710 | 817 | 61 | 4.13 | 37.20 | 2254.8 | 241.07 | 0.0407 |

| 800 | 921 | 61 | 4.38 | 39.50 | 2540.6 | 271.62 | 0.0361 |

| 900 | 1036 | 91 | 3.81 | 41.80 | 2861.1 | 305.58 | 0.0321 |

| 1000 | 1151 | 91 | 4.01 | 44.10 | 3179.0 | 339.53 | 0.0289 |

| 1120 | 1289 | 91 | 4.25 | 46.70 | 3560.5 | 380.27 | 0.0258 |

| 1250 | 1439 | 91 | 4.49 | 49.40 | 3973.7 | 424.41 | 0.0231 |

Huili Cable Co., Ltd. (formerly Luohe Huili Cable Co., Ltd. and Luohe Cable Factory) was founded in 1989 and was renamed Huili Cable Co., Ltd. on September 14, 2024. The company's registered capital is RMB 200 million.