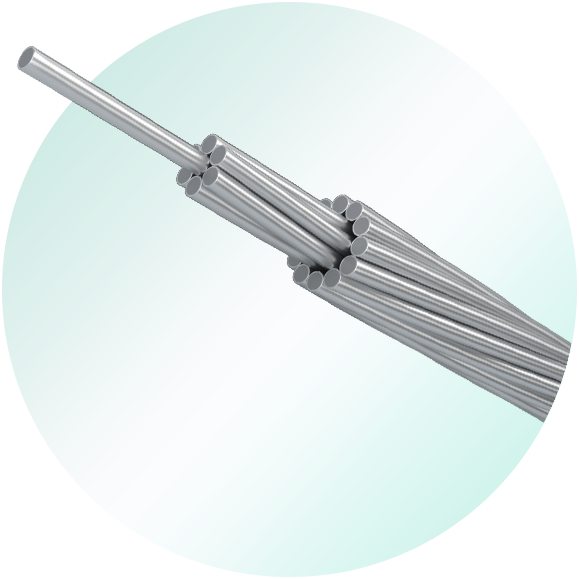

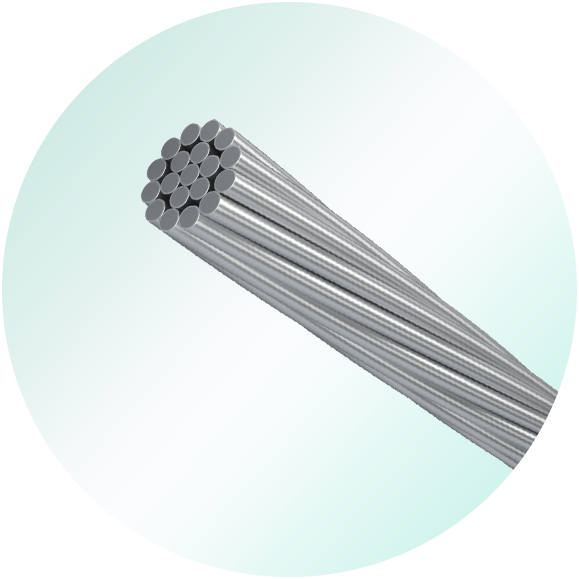

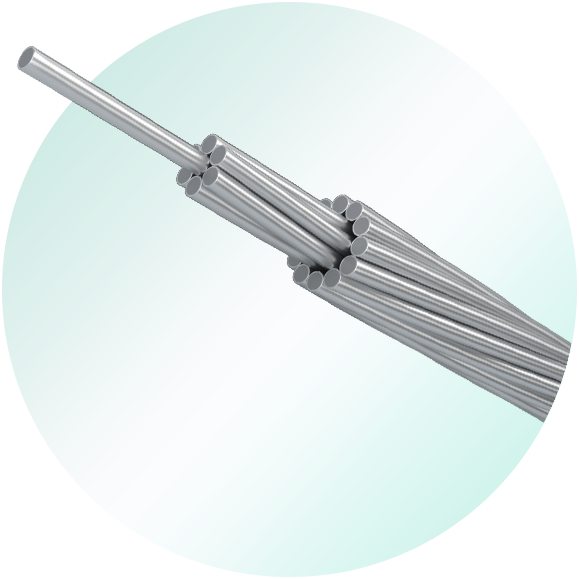

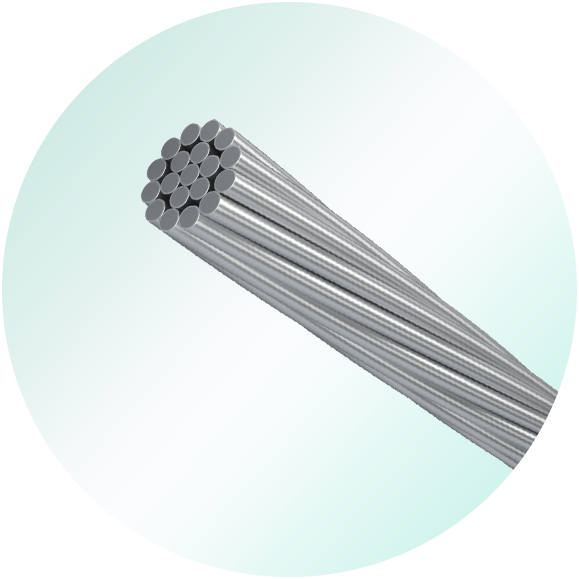

ACS - Aluminum Clad Steel Conductor

Bare concentric-lay-stranded conductors made from bare, hard-drawn, round, aluminum clad steel wires for general use of electrical purposes.

Home > Products > Bare Conductor

Bare concentric-lay-stranded conductors made from bare, hard-drawn, round, aluminum clad steel wires for general use of electrical purposes.

Aluminum clad steel conductor finds extensive use in various scenarios including long-span transmission lines, coastal and island regions, salt alkali beach, and grade 3 or grade 4 polluted industrial zone. Due to its excellent characteristics, this product is used extensively in the cable industry for the manufacturing of Optical Ground Wire (OPGW), conventional stranded earth wired and steel reinforced cores for phases conductors, all to be used in overheads lines. Also, it can be used in alternative applications an helical hardware for overhead lines or those where the resistance to the corrosion is an important factor.

Bare concentric-lay-stranded conductors made from bare, hard-drawn, round, aluminum clad steel wires for general use of electrical purposes. Conductors are classified as follows: 14 % conductivity, 20.3 % conductivity, 27 % conductivity, 35 % conductivity, 40 % conductivity.

Aluminum-Clad Steel Conductor is a bimetallic wire which steel wire is covered by aluminum evenly, offering a unique blend of strength and conductivity, making it an optimal choice for efficiently transmitting electrical power over extensive distances. It features anti-corrosion, good high frequency transmission and high intensity.

Concentric-Lay-Stranded Aluminum-Clad Steel Conductors

Steel Conductors and stays Bare Overhead Part 2: Aluminum clad (SC/AC)

Round wire concentric lay overhead electrical stranded conductors

Round wire concentric lay overhead electrical stranded conductors

| Size Designation | Nominal Cross Section | Number and Diameter of Individual Wires |

Conductor Diameter |

Mass per Unit Length | Min.Rated Breaking Strength | Max. DC Resistance at 20℃ | |

| Number | Nominal Diameter |

||||||

| mm2 | mm | mm | kg/km | kN | Ω/km | ||

| 37 No. 5 AWG | 620.58 | 37 | 4.620 | 32.26 | 4169.8 | 635.42 | 0.1393 |

| 37 No. 6 AWG | 492.19 | 37 | 4.115 | 28.70 | 3306.7 | 534.86 | 0.1757 |

| 37 No. 7 AWG | 390.32 | 37 | 3.665 | 25.65 | 2622.1 | 448.09 | 0.2216 |

| 37 No. 8 AWG | 309.55 | 37 | 3.264 | 22.83 | 2080.4 | 374.67 | 0.2794 |

| 37 No. 9 AWG | 245.48 | 37 | 2.906 | 20.35 | 1648.9 | 297.11 | 0.3524 |

| 37 No. 10 AWG | 194.64 | 37 | 2.588 | 18.11 | 1308.1 | 235.61 | 0.4442 |

| 19 No. 5 AWG | 318.71 | 19 | 4.620 | 23.11 | 2128.1 | 326.39 | 0.2698 |

| 19 No. 6 AWG | 252.71 | 19 | 4.115 | 20.57 | 1687.6 | 274.55 | 0.3402 |

| 19 No. 7 AWG | 200.45 | 19 | 3.665 | 18.31 | 1338.6 | 230.18 | 0.4292 |

| 19 No. 8 AWG | 158.97 | 19 | 3.264 | 16.31 | 1061.8 | 192.41 | 0.5410 |

| 19 No. 9 AWG | 126.06 | 19 | 2.906 | 14.53 | 842.0 | 152.58 | 0.6821 |

| 19 No. 10 AWG | 99.94 | 19 | 2.588 | 12.93 | 667.7 | 120.99 | 0.8603 |

| 7 No. 5 AWG | 117.42 | 7 | 4.620 | 13.87 | 781.1 | 120.28 | 0.7428 |

| 7 No. 6 AWG | 93.10 | 7 | 4.115 | 12.34 | 619.5 | 101.14 | 0.9197 |

| 7 No. 7 AWG | 73.87 | 7 | 3.665 | 11.00 | 491.1 | 84.81 | 1.1598 |

| 7 No. 8 AWG | 58.56 | 7 | 3.264 | 9.78 | 389.6 | 70.88 | 1.4627 |

| 7 No. 9 AWG | 46.44 | 7 | 2.906 | 8.71 | 308.9 | 56.20 | 1.8443 |

| 7 No. 10 AWG | 36.83 | 7 | 2.588 | 7.77 | 245.1 | 44.59 | 2.3256 |

| 7 No. 11 AWG | 29.18 | 7 | 2.304 | 6.91 | 194.4 | 35.35 | 2.9326 |

| 7 No. 12 AWG | 23.16 | 7 | 2.052 | 6.15 | 154.2 | 28.04 | 3.6977 |

| 3 No. 5 AWG | 50.32 | 3 | 4.620 | 9.96 | 334.1 | 54.42 | 1.6986 |

| 3 No. 6 AWG | 39.90 | 3 | 4.115 | 8.86 | 265.0 | 45.74 | 2.1418 |

| 3 No. 7 AWG | 31.65 | 3 | 3.665 | 7.90 | 210.1 | 38.36 | 2.7009 |

| 3 No. 8 AWG | 25.10 | 3 | 3.264 | 7.04 | 166.7 | 32.06 | 3.4057 |

| 3 No. 9 AWG | 19.90 | 3 | 2.906 | 6.27 | 132.2 | 25.43 | 4.2948 |

| 3 No. 10 AWG | 15.78 | 3 | 2.588 | 5.59 | 104.8 | 20.17 | 5.4169 |

| Stranding and Wire Diameter | Approx. Overall Diameter | Cross-Sectional Area |

Approx. Mass per km | Calculated Breaking Load (CBL) | Equivalent Aluminium Area | Direct Current Resistance per km at 20°C |

| mm | mm | mm² | kg | kN | mm² | Ω |

| 3/2.75 | 5.93 | 17.82 | 118 | 22.7 | 5.91 | 4.80 |

| 3/3.00 | 6.47 | 21.21 | 141 | 27.0 | 7.03 | 4.02 |

| 3/3.25 | 7.00 | 24.89 | 165 | 31.6 | 8.26 | 3.42 |

| 3/3.75 | 8.08 | 33.12 | 220 | 39.3 | 11.0 | 2.58 |

| 7/2.75 | 8.25 | 41.58 | 277 | 50.1 | 13.7 | 2.06 |

| 7/3.00 | 9.00 | 49.48 | 330 | 59.7 | 16.3 | 1.73 |

| 7/3.25 | 9.75 | 58.07 | 387 | 69.9 | 19.2 | 1.47 |

| 7/3.75 | 11.3 | 77.28 | 515 | 86.9 | 25.5 | 1.11 |

| 7/4.25 | 12.8 | 99.33 | 662 | 105 | 32.8 | 0.864 |

| 19/2.75 | 13.8 | 112.9 | 755 | 136 | 37.1 | 0.764 |

| 19/3.00 | 15.0 | 134.3 | 899 | 162 | 44.1 | 0.642 |

| 19/3.25 | 16.3 | 157.6 | 1060 | 189 | 51.8 | 0.545 |

| 19/3.75 | 18.8 | 209.8 | 1410 | 236 | 68.9 | 0.411 |

| 19/4.25 | 21.3 | 269.6 | 1800 | 286 | 88.6 | 0.320 |

Huili Cable Co., Ltd. (formerly Luohe Huili Cable Co., Ltd. and Luohe Cable Factory) was founded in 1989 and was renamed Huili Cable Co., Ltd. on September 14, 2024. The company's registered capital is RMB 200 million.