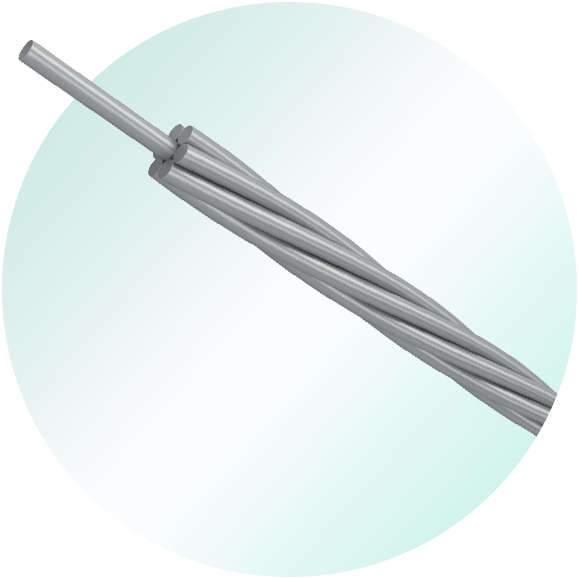

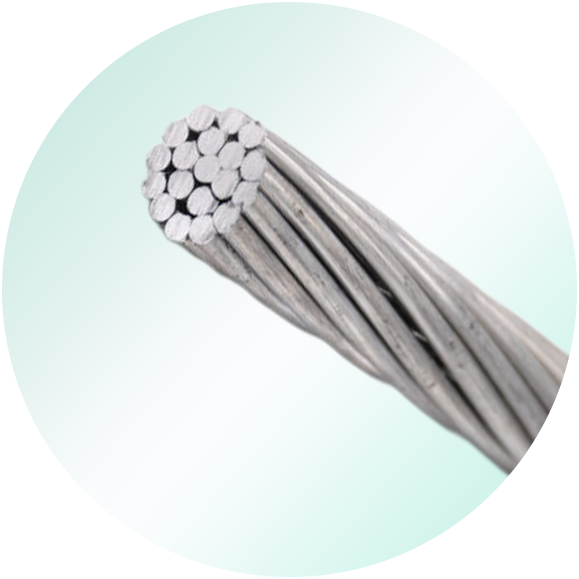

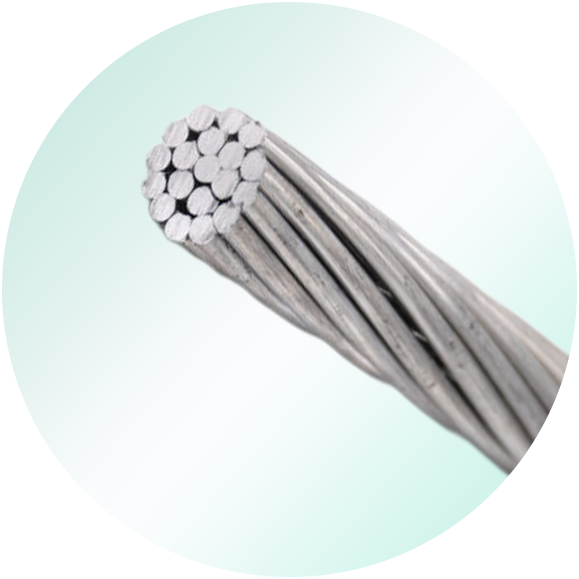

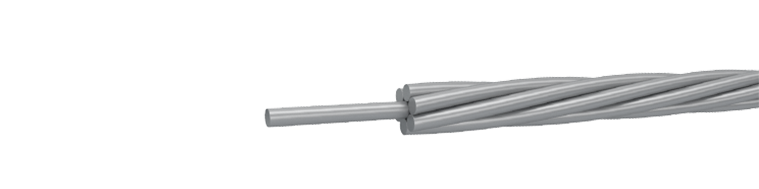

GSW-Galvanized Steel Wire Strand

The galvanized single steel wires or stranded steel wires are suitable for cores of ACSR to improve its tensile strength. It’s still usually use for steel core for stay wire or guy wire.

Home > Products > Bare Conductor

The galvanized single steel wires or stranded steel wires are suitable for cores of ACSR to improve its tensile strength. It’s still usually use for steel core for stay wire or guy wire.

The galvanized single steel wires or stranded steel wires are suitable for cores of ACSR to improve its tensile strength. It’s still usually use for steel core for stay wire or guy wire. And they can also be used in the aerial transmission line as the line material of ground connection to avoid the lightning strike.

Bare concentric-lay-stranded conductors are made from bare, hard-drawn, round, aluminum clad steel wires for general use of electrical purposes. The galvanized steel wire made from fully-killed steel with a carbon content of 0.6%, it is galvanized by either a hot dip or electrolytic process to give a zinc coating layer. Tensile strength and zinc-clad of steel wire have different grades.

The galvanized steel wire strand available in class "A", "B" and "C" galvanizing, "A" being the least heavy and "C" being the most heavy, each grade corresponding to different tensile strength. Its low cost and ease of production makes galvanized steel wire ideal for mass produced corrosion resistant wire products, which is indispensable in industrial, agricultural.

Zinc-Coated Steel Wire Strand

General Purpose Galvanized Steel Wire Strand

Round wire concentric lay overhead electrical stranded conductors

Round wire concentric lay overhead electrical stranded conductors

| Nominal Diameter of Strand | Number of Wires in Strand | Nominal Diameter of Coated Wires in Strand | Approx. Weight of Strand |

Minimun Breaking Strength of Strand | |||||

| Utilities Grade | Common Grade | Siemens- Martin Grade |

High- Strength Grade |

Extra-high Strength Grade | |||||

| In. | mm | No. | mm | kg/km | kN | kN | kN | kN | kN |

| 1/8 | 3.18 | 7 | 1.04 | 48 | - | 2.402 | 4.048 | 5.916 | 8.140 |

| 5/32 | 3.97 | 7 | 1.32 | 76 | - | 3.870 | 6.539 | 9.519 | 13.078 |

| 3/16 | 4.76 | 7 | 1.57 | 109 | - | 5.115 | 8.452 | 12.677 | 17.748 |

| 3/16 | 4.76 | 7 | 1.65 | 119 | 10.676 | - | - | - | - |

| 7/32 | 5.56 | 3 | 2.64 | 131 | - | 6.228 | 10.409 | 15.569 | 21.796 |

| 7/32 | 5.56 | 7 | 1.83 | 146 | - | 6.850 | 11.387 | 17.126 | 24.020 |

| 1/4 | 6.35 | 3 | 3.05 | 174 | 14.012 | 8.274 | 13.523 | 21.040 | 29.981 |

| 1/4 | 6.35 | 3 | 3.05 | 174 | 20.017 | - | - | - | - |

| 1/4 | 6.35 | 7 | 2.03 | 180 | - | 8.452 | 14.012 | 21.129 | 29.581 |

| 9/32 | 7.14 | 3 | 3.30 | 204 | - | 9.252 | 15.035 | 23.398 | 33.362 |

| 9/32 | 7.14 | 7 | 2.36 | 244 | 20.462 | 11.432 | 18.905 | 28.469 | 39.812 |

| 5/16 | 7.94 | 3 | 3.68 | 255 | 28.913 | 11.076 | 18.193 | 28.246 | 40.479 |

| 5/16 | 7.94 | 7 | 2.64 | 305 | - | 14.234 | 23.798 | 35.586 | 49.820 |

| 5/16 | 7.94 | 7 | 2.77 | 335 | 26.689 | - | - | - | - |

| 3/8 | 9.52 | 3 | 4.19 | 328 | 37.810 | 14.813 | 24.732 | 37.187 | 52.489 |

| 3/8 | 9.52 | 7 | 3.05 | 407 | 51.155 | 18.905 | 30.915 | 48.040 | 68.503 |

| 7/16 | 11.11 | 7 | 3.68 | 595 | 80.068 | 25.355 | 41.591 | 64.499 | 92.523 |

| 1/2 | 12.70 | 7 | 4.19 | 770 | 111.206 | 32.917 | 53.823 | 83.627 | 119.657 |

| 1/2 | 12.70 | 19 | 2.54 | 751 | - | 33.895 | 56.492 | 84.961 | 118.768 |

| 9/16 | 14.29 | 7 | 4.78 | 1000 | - | 42.703 | 69.837 | 108.981 | 155.688 |

| 9/16 | 14.29 | 19 | 2.87 | 949 | - | 42.881 | 71.616 | 107.202 | 149.905 |

| 5/8 | 15.88 | 7 | 5.26 | 1211 | - | 51.599 | 84.961 | 131.667 | 188.605 |

| 5/8 | 15.88 | 19 | 3.18 | 1186 | - | 48.930 | 80.513 | 124.995 | 178.819 |

| 3/4 | 19.05 | 19 | 3.81 | 1721 | - | 71.172 | 116.543 | 181.487 | 259.331 |

| 7/8 | 22.22 | 19 | 4.50 | 2356 | - | 97.416 | 159.691 | 248.211 | 354.523 |

| 1 | 25.40 | 19 | 5.08 | 3089 | - | 127.664 | 209.066 | 325.610 | 464.839 |

| 1 | 25.40 | 37 | 3.63 | 3065 | - | 125.885 | 205.508 | 319.827 | 456.832 |

| 1 1/8 | 28.58 | 37 | 4.09 | 4010 | - | 160.136 | 262.000 | 407.457 | 581.827 |

| 1 1/4 | 31.75 | 37 | 4.55 | 4840 | - | 198.391 | 324.720 | 505.318 | 721.502 |

| Note:Class A and Class B and Class C are in same structure. | |||||||||

| Construction Number of wires/wire diameter | Approximate strand diameter | Minimum breaking load of strand | Approx. mass |

||||||

| Grade 350 | Grade 480 | Grade 700 | Grade 850 | Grade 1000 | Grade 1150 | Grade 1300 | |||

| mm | kN | kN | kN | kN | kN | kN | kN | kg/km | |

| 3/1.80 | 3.9 | 2.65 | 3.66 | — | — | — | — | — | 60 |

| 3/2.65 | 5.7 | 5.80 | 7.95 | — | — | — | — | — | 130 |

| 3/3.25 | 7.0 | 8.70 | 11.95 | — | — | — | — | — | 195 |

| 3/4.00 | 8.6 | 13.20 | 18.10 | — | — | — | — | — | 295 |

| 4/1.80 | 4.4 | 3.55 | 4.90 | — | — | — | — | — | 80 |

| 4/2.65 | 6.4 | 7.70 | 10.60 | — | — | — | — | — | 172 |

| 4/3.25 | 7.9 | 11.60 | 15.90 | — | — | — | — | — | 260 |

| 4/4.00 | 9.7 | 17.60 | 24.10 | 35.20 | — | — | — | — | 390 |

| 5/1.50 | 4.1 | 3.10 | 4.24 | 6.18 | — | — | — | — | 69 |

| 5/1.80 | 4.9 | 4.45 | 6.10 | 8.90 | — | — | — | — | 95 |

| 5/2.65 | 7.2 | 9.65 | 13.25 | 19.30 | — | — | — | — | 220 |

| 5/3.25 | 8.8 | 14.50 | 19.90 | 29.00 | — | — | — | — | 320 |

| 5/4.00 | 10.8 | 22.00 | 30.15 | 43.95 | — | — | — | — | 490 |

| 7/0.56 | 1.7 | 0.60 | 0.83 | 1.20 | — | 1.70 | 1.98 | 2.24 | 14 |

| 7/0.71 | 2.1 | 0.97 | 1.33 | 1.94 | — | 2.75 | 3.19 | 3.60 | 28 |

| 7/0.85 | 2.6 | 1.39 | 1.90 | 2.80 | — | 3.95 | 4.57 | 5.15 | 31 |

| 7/0.90 | 2.7 | 1.55 | 2.14 | 3.10 | — | 4.45 | 5.12 | 5.80 | 35 |

| 7/1.00 | 3.0 | 1.92 | 2.64 | 3.85 | — | 5.50 | 6.32 | 7.15 | 43 |

| 7/1.25 | 3.8 | 3.01 | 4.10 | 6.00 | — | 8.55 | 9.88 | 11.15 | 67 |

| 7/1.40 | 4.2 | 3.75 | 5.17 | 7.54 | 9.16 | 10.75 | 12.35 | 14.00 | 84 |

| 7/RSC | 4.3 | 3.85 | 5.28 | 7.70 | 9.35 | 11.00 | 12.65 | 14.30 | 86 |

| 7/1.60 | 4.8 | 4.90 | 6.75 | 9.85 | 11.95 | 14.10 | 16.20 | 18.30 | 110 |

| 7/1.80 | 5.4 | 6.23 | 8.55 | 12.45 | — | 17.80 | 20.50 | 23.20 | 140 |

| 7/2.00 | 6.0 | 7.70 | 10.55 | 15.40 | — | 22.00 | 25.30 | 28.60 | 170 |

| 7/2.36 | 7.1 | 10.70 | 14.70 | 21.40 | — | 30.60 | 35.20 | 39.80 | 240 |

| 7/2.65 | 8.0 | 13.50 | 18.50 | 27.00 | — | 38.60 | 44.40 | 50.20 | 300 |

| 7/3.00 | 9.0 | 17.30 | 23.75 | 34.65 | — | 49.50 | 56.90 | 64.30 | 392 |

| 7/3.15 | 9.5 | 19.10 | 26.20 | 38.20 | — | 54.55 | 62.75 | 70.90 | 430 |

| 7/3.25 | 9.8 | 20.30 | 27.85 | 40.65 | — | 58.05 | 66.80 | 75.50 | 460 |

| 7/3.65 | 11.0 | 25.60 | 35.15 | 51.25 | — | 73.25 | 84.20 | 95.20 | 570 |

| 7/4.00 | 12.0 | 30.90 | 42.20 | 61.60 | — | 88.00 | 101.00 | 114.00 | 690 |

| 7/4.25 | 12.8 | 34.75 | 47.65 | 69.50 | — | 99.30 | 114.00 | 129.00 | 780 |

| 7/4.75 | 14.0 | 43.40 | 59.45 | 86.80 | — | 124.00 | 142.70 | 161.30 | 970 |

| 19/1.00 | 5.0 | 5.22 | 7.16 | 10.45 | — | 14.92 | 17.16 | 19.40 | 120 |

| 19/1.25 | 6.3 | 8.16 | 11.19 | 16.32 | — | 23.32 | 26.81 | 30.31 | 180 |

| 19/1.40 | 7.0 | 10.24 | 14.04 | 20.47 | — | 29.25 | 33.64 | 38.02 | 230 |

| 19/1.60 | 8.0 | 13.37 | 18.34 | 26.75 | — | 38.20 | 43.93 | 49.66 | 300 |

| 19/2.00 | 10.0 | 20.90 | 28.65 | 41.78 | 50.74 | 59.69 | 68.64 | 77.60 | 470 |

| 19/2.50 | 12.5 | 32.65 | 44.80 | 65.29 | 79.28 | 93.27 | 107.30 | 121.30 | 730 |

| 19/3.00 | 15.0 | 47.00 | 64.50 | 94.00 | 114.10 | 134.30 | 154.50 | 174.60 | 1050 |

| 19/3.55 | 17.8 | 65.80 | 90.27 | 131.60 | 159.90 | 188.00 | 216.30 | 244.50 | 1470 |

| 19/4.00 | 20.0 | 83.55 | 114.60 | 167.10 | 203.00 | 238.70 | 274.60 | 310.40 | 1870 |

| 19/4.75 | 23.8 | 117.85 | 161.60 | 235.70 | 286.00 | 336.70 | 387.20 | 437.70 | 2630 |

| Code Number |

Area | Number of Wires单丝根数 | Diameter | Linear Mass |

Rated Strength | ||||

| Wire | Cond. | S1A | S1B | S2A | S3A | ||||

| mm2 | No. | mm | mm | kg/km | kN | kN | kN | kN | |

| 4 | 27.1 | 7 | 2.22 | 6.66 | 213.3 | 36.3 | 33.6 | 39.3 | 43.9 |

| 6.3 | 42.7 | 7 | 2.79 | 8.36 | 335.9 | 55.9 | 51.7 | 60.2 | 67.9 |

| 10 | 67.8 | 7 | 3.51 | 10.53 | 553.2 | 87.4 | 80.7 | 93.5 | 103.0 |

| 12.5 | 84.7 | 7 | 3.93 | 11.78 | 666.5 | 109.3 | 100.8 | 116.9 | 128.8 |

| 16 | 108.4 | 7 | 4.44 | 13.32 | 853.1 | 139.9 | 129.0 | 199.7 | 164.8 |

| 16 | 108.4 | 19 | 2.70 | 13.48 | 857.0 | 142.1 | 131.2 | 152.9 | 172.4 |

| 25 | 169.4 | 19 | 3.37 | 16.85 | 1339.1 | 218.6 | 201.6 | 238.9 | 262.6 |

| 40 | 271.1 | 19 | 4.26 | 21.31 | 2141.6 | 349.7 | 322.6 | 374.1 | 412.1 |

| 40 | 271.1 | 37 | 3.05 | 21.38 | 2148.1 | 349.7 | 322.6 | 382.3 | 420.2 |

| 63 | 427.0 | 37 | 3.83 | 26.83 | 3383.2 | 550.8 | 508.1 | 589.3 | 649.0 |

Huili Cable Co., Ltd. (formerly Luohe Huili Cable Co., Ltd. and Luohe Cable Factory) was founded in 1989 and was renamed Huili Cable Co., Ltd. on September 14, 2024. The company's registered capital is RMB 200 million.